Professional engineers will come to work at your call.

There are cases where machinery malfunctions, configurations are lost, and unexpected stoppages occur.

If additional manpower and professional engineers are needed to restore the factory to normal operation, please contact us.

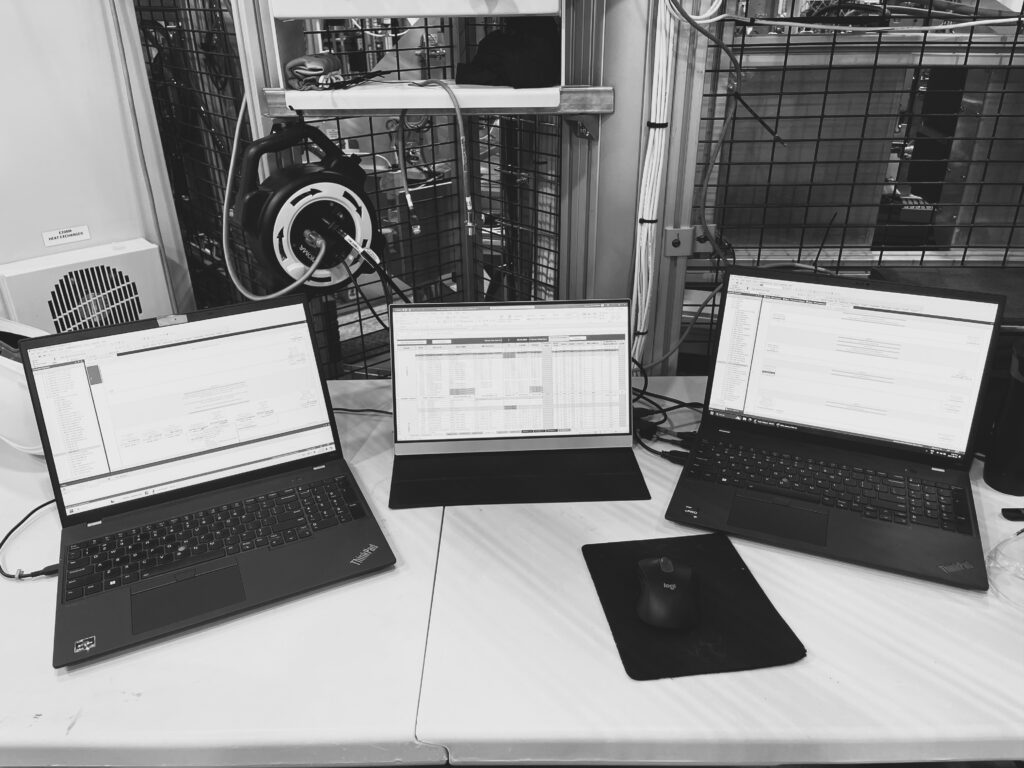

Emergency Engineer

Automation engineers understand the complete line operation process and determine work sequences to repair breakdowns and stoppages.

Common problems we solve:

- Protection equipment, relay blocking configuration failures.

- Replacing old or outdated PLCs, frequency converters and other equipment.

- Equipment running too slowly, abnormally, or stopping unexpectedly.

- Loss of inter-equipment relationships, fine-tuning of relationships.

- Synchronization loss in equipment with multiple servo motors such as packers, baggers, baggers.

- Professional training, consultation, testing, certification, etc.

Working quickly and getting the factory back to normal operation quickly directly affects our reputation. Therefore, we work with quality, responsibility, safety, and speed as our priorities.